Videos

Bohren und Gewindeschneiden in einem einfachen Vorgang

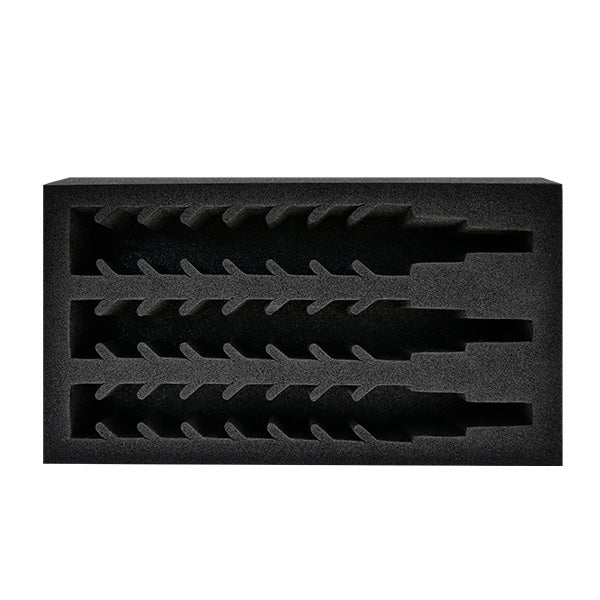

VersaDrive® Heavy Duty Impacta-Drill Gewindebohrer sind ein industrielles Metallbearbeitungs- oder Fertigungswerkzeug zum Bohren und Gewindeschneiden von schwerem Stahl in einem einfachen Arbeitsgang.

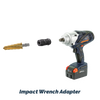

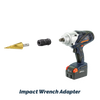

In erster Linie sind sie für die Verwendung mit einem reversiblen Magnetbohrer konzipiert, können aber auch für die Verwendung mit einem Schlagschrauber angepasst werden, um vorhandene Löcher zu vergrößern und Gewinde zu schneiden.

Mit einer Bohrerspitze, die für den Einsatz in stationären Bohrmaschinen wie Magnetbohrern oder Säulenbohrern optimiert ist, werden diese nicht für den Einsatz in einer Pistolenbohrmaschine empfohlen. Wo sie mit einem Schlagschrauber zum Aufweiten und Gewindebohren verwendet werden sollen, wird eine Vorbohrung mit einem separaten Bohrer empfohlen.

Produkt Vorteile

- Schnelles Klopfen mit minimalem Rückschlag

- Speziell gehärtet für den Einsatz als Schlagschrauber

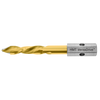

- Hochwertiger Werkzeugstahl für hohe Genauigkeit und lange Lebensdauer

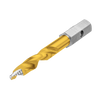

- GoldMax reibungsarme Titanbeschichtung, um Ausbrennen zu verhindern

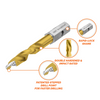

- Hochfestes, rutschfestes Schaftdesign Einzigartiger Dual-Point-Anfangswinkel für einfache Ausrichtung und schnellen Schnitt

- Geschliffener Spiralbohrer Erzeugt das perfekte Kernloch

- Spanbrecheraktion für automatische Spanabfuhr beim Schlagbohren

- Hochfestes, rutschfestes Schaftdesign

Kurzanleitung

- Die richtige Drehzahl ist entscheidend für eine gute Leistung bei größeren Bohrgewindebohrern

- Ideal für den Einsatz in Bohrmaschinen und Magnetbohrmaschinen

- Für die Verwendung mit einem Schlagschrauber muss das Loch mit einem separaten Bohrer vorgebohrt werden

- Verwenden Sie eine geeignete Schmierung und die richtige Drehzahl, um eine lange Lebensdauer des Werkzeugs zu erreichen