Videos

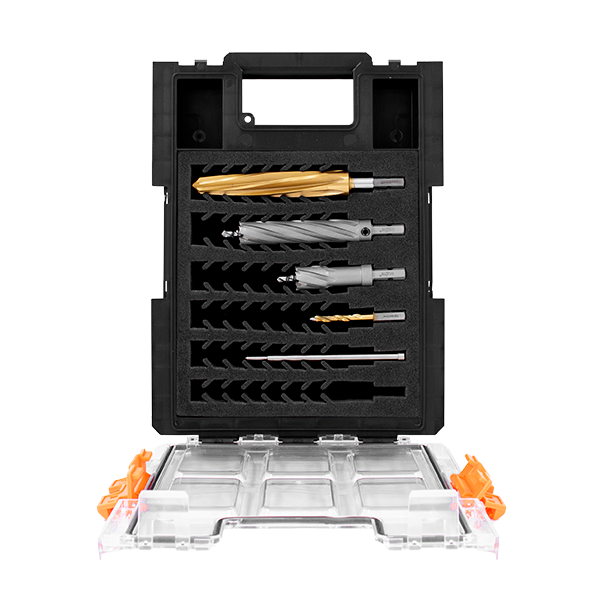

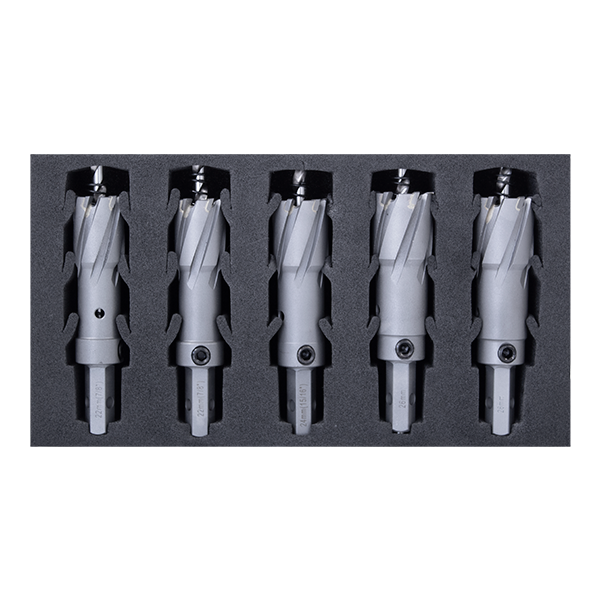

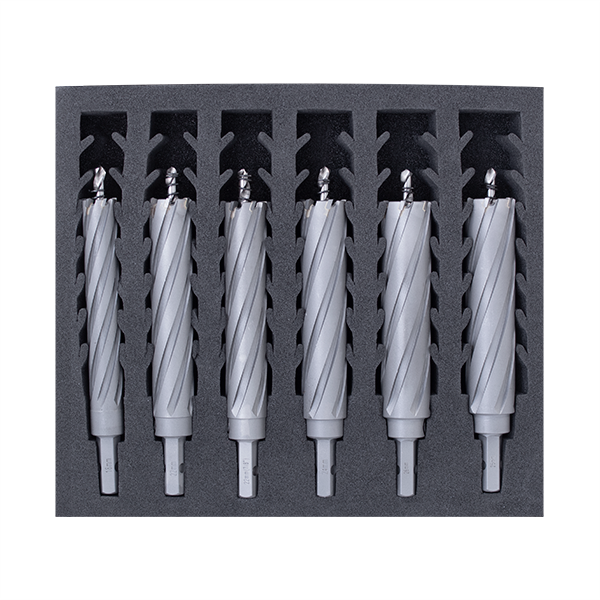

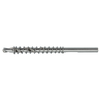

Die CarbideMax™ 110-Serie räumt bis zu 110 mm Metalldicke. Einzeln gelötete Schneidzähne sind aus Wolframcarbid gefertigt, das in der Lage ist, durch die härtesten Stähle zu bohren.

- Bis zu 10x längere Lebensdauer als herkömmliche HSS-Fräser

- 64 % schnellere Schnitte als HSS-Fräser

- Ausgeklügelte Schneidengeometrie für schnelleres, leiseres Bohren

- Chatterfreie Leistung

Das HMT CarbideMax-Sortiment verwendet hochwertige Sandvik-Wolframcarbidzähne, eines der härtesten Materialien, die für den Einsatz in Schneidwerkzeugen erhältlich sind. Dies bedeutet, dass Fräser in der Lage sind, durch die härtesten Stähle zu bohren, während sie ihre Festigkeit und Schneidfläche bis zu 10x länger als herkömmliche HSS-Fräser beibehalten.

Die ausgeklügelte Geometrie der CarbideMax-Räumfräser sorgt dafür, dass die Zähne des Fräsers die ganze Arbeit erledigen. Dies reduziert die Belastung des Werkzeugkörpers und bedeutet, dass eine starke, aber dünne flexible Legierung für seine Konstruktion verwendet werden kann.

Dünnere Wände bedeuten, dass CarbideMax-Werkzeuge weniger Material vom Werkstück entfernen müssen, was zu einem schnelleren Schnitt und einem leiseren, einfacheren Bohren führt.

CarbideMax - mehr Löcher, schneller, länger. Unglaubliches Preis-Leistungs-Verhältnis, höhere Effizienz auf der Baustelle und weniger Stopps, da weniger Werkzeuge nachbestellt und ersetzt werden müssen.