Videos

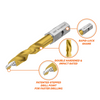

VersaDrive Senker 90°

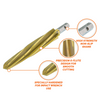

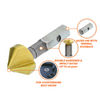

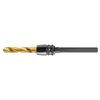

Der VersaDrive-Senker ist ein hochwertiger Senker mit vollständig geschliffenen Spannuten und einer Titanbeschichtung, um Verschleiß und Abstumpfung zu reduzieren.

VersaDrive®-Senker haben einen patentierten rutschfesten Sechskantschaft, der für den Einsatz in jedem standardmäßigen 1/2-Zoll-Bohrfutter für Akku- oder Pistolenbohrer geeignet ist oder mit einem VersaDrive Rapid Lock-Adapter für den Einsatz in einer Vielzahl von Elektrowerkzeugen wie Magnetbohrern verwendet werden kann.

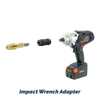

Nutzen Sie den Komfort und die Kraft eines Schlagschraubers zum schnellen Entgraten und Senken von Löchern bis zu 16,5 mm mit minimalem Drehmomentrückschlag gegen den Bediener.

Produkt Vorteile

- 90º Spitzenwinkel für Senkschraubenköpfe

- Sicherer Gebrauch mit minimalem Rückschlag

- Speziell gehärtet für den Schlagschraubereinsatz bis 16,5 mm

- Hochwertiger Werkzeugstahl für hohe Genauigkeit und lange Lebensdauer

- Reibungsarme GoldMax-Titanbeschichtung, um das Ausbrennen zu verhindern

- Hochfestes, rutschfestes Schaftdesign

- 1. schlagfeste Senker auf dem Markt

Kurzanleitung

- Optimale Lebensdauer und Leistung bei Verwendung mit Rotations-Pistolenbohrmaschinen oder Bohrmaschinen

- Bis zu 16,5 mm können für Schlagschrauber und Schlagschrauber für schnelle Schneidleistung verwendet werden

- Geeignet für härtere Materialien wie Edelstahl bei Verwendung mit reduzierter Drehzahl

- Verwenden Sie eine geeignete Schmierung und die richtige Drehzahl, um eine lange Lebensdauer des Werkzeugs zu erreichen